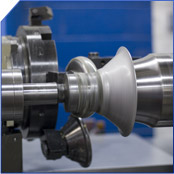

Precision Wire Products works closely with Lewark Metal Spinning to provide our customers with the highest quality, most economical spinning. They use metal-spinning lathes, hydraulic assist machines, and specialized equipment. The results are superior to shear forming. They have a number of benefits, including shorter lead times, lower costs, less waste, design flexibility, and so much more.

An array of materials can be used. They can work on diameters ranging from .250 to 72 inches, and thicknesses up to .250 inches. Tolerances of .002 inches can be reached. Spinning can be used for our filter cages, filter rings, and other products. They have several intended applications, including use in aerospace and ground power turbine generation. A variety of tooling is available.

Like all of our products and services, we proudly stand behind the spinning we provide through Lewark Metal Spinning. Please contact us with any questions, and see below for details.